Click here to edit your subtitle

Click here to edit your description

Logistics Technology

has evolved far beyond transshipment point modeling and just in time planning. Modern logistics involves numerous operational challenges that are not part of traditional logistics planning models. Problems such as massive driver shortages and continental supply chain back orders require newer technologies such as block chain and agile frameworks that support responsive forecasting. This exploratory knowledge sharing platform is meant to host discussions that bridge legacy systems with revitalized methodologies for 2023.

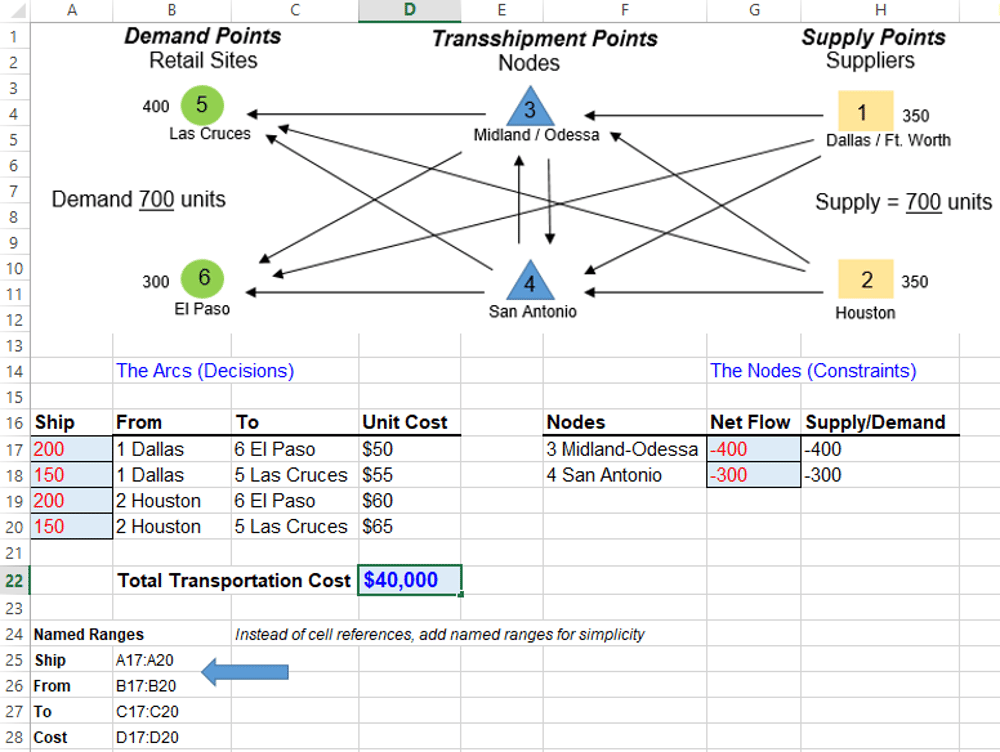

The Transshipment model pictured represents the inject of nodes that balance supply with demand between suppliers and retail sites. The inject of transshipment nodes is an optimization model that uses linear programming to provide dispatchers the ability to make data driven routing decisions. This optimization method has been around for decades, is it time for an improvement? Let’s discuss.

Equipment Lifecycle Management

In this slightly more granular review of equipment lifecycle management, I use the same notional scenario for the review of a 10,000lb telehandler forklift to perform a lifecycle assessment. I attempt to demonstrate the value of using a costing analysis to chart out a course for replacement and inject some predictive analysis into the telehandler’s equipment lifecycle. With no formal analysis structure or industry defined process, I attempt to piece together a few tools to show “a way”. In the end, whatever analysis you perform is going to benefit your organization and assist with some kind of predictive analysis. After all, that’s the end state – to provide your executive leadership with a data driven analysis to predict future overhaul, retrofit or recapitalization expenses ahead of the failure.

Blockchain to address Port Congestion?

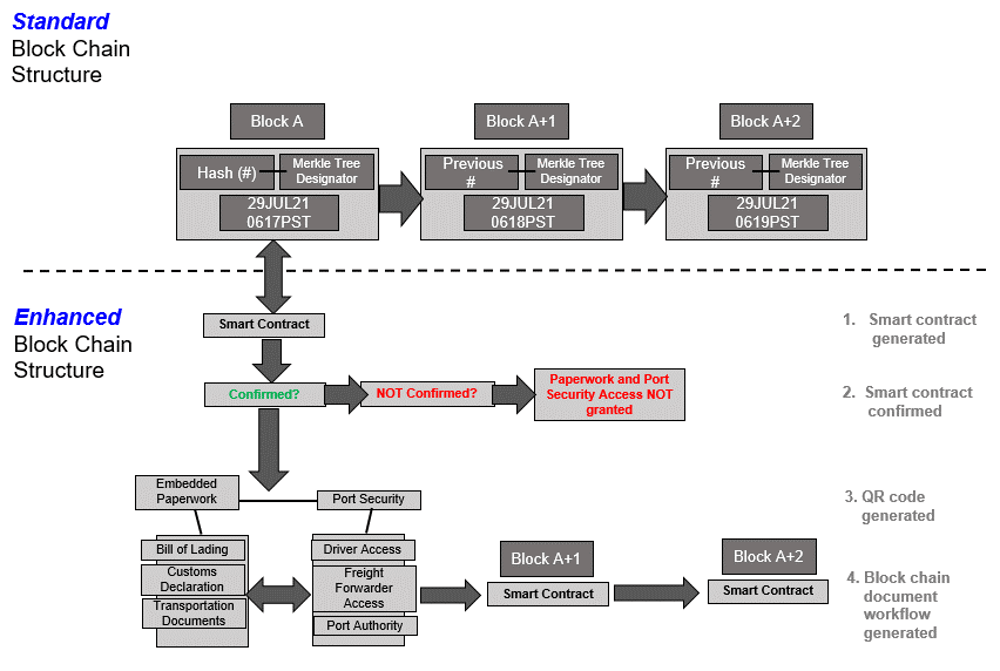

Block chain tech employs cryptography through the use of an immutable ledger to track assets. This technology may be of great use to logisticians, supply chain managers, freight forwarders and port authority personnel. Not only could it expedite movements, but it has tremendous potential for optimizing work flows and enhancing security. The port congestion of the past two years has illustrated how our current disjointed system is inadequate and even dangerous in many respects. It’s time for a full review of qualitative process at the ports and a possible revitalization of systems employed. If we dig a little deeper into this concept, there are a multitude of applications to explore. One in particular may be to provide an additional layer of protected information. This layer could act as a sort of carrier for operational and security information. Impenetrable security that is transmitted in real time has the potential to transform our ports and supply chain into precisely managed networks.

The Smart Contract

An enhanced version applied for logistics management at our ports may include the use of what is called a smart contract. The smart contract would work by creating a logic agreement to broaden functionality. An if/else statement could be used as part of the sequenced agreement to also be checked by the principle algorithm. If/else statements signify that if two conditions are mutually exclusive then if one condition is true, the other statement must be false. They are commonly used in programming languages such as SQL, Java and Python. Once the if/else statement result is checked by the algorithm and confirmed, the system could then add a layer and transfer additional information to the ledger. This may include digital copies of all of the transaction documentation that are relevant to a particular movement. This would then create a block chain generated document workflow to either replace or parallel current workflow processes in place. An adjacent data set may include operational security information to get secure information transmitted immediately to the people who need it quickly – this is key at the ports.

For instance, imagine if a driver or container handler could instantly receive a completely verified QR code in real time that instructed him/her precisely what actions to take. Wait times could be instantly reduced, operational confusion minimized and security increased immeasurably.

In the current system, document workflows are clumsily verified though ERP modules, regular paper trails, e-mails even phone calls. The potential for errors, miscommunication and even falsification are tremendous and often lead to unnecessary delays and poorly routed shipments. These are major inefficiencies that create an abundance of waste and defect in all manner of transportation activities. A blockchain driven document workflow would maximize visibility for all nodes while providing an ability to provide live updates to each smart contract block as they are created. Because of the failsafe logic agreement, suspicious actions would be rejected meaning that approvals could come automatically and seamlessly. A history of document workflow will have been instantly created that lends to efficiencies at all levels. A nice ancillary benefit may be the trust that is established as an inherent part of this entire process, nodes can communicate and work together in confidence under an umbrella of complete security.

Inventory Management

The Sabarnes-Oxley Act is a federal law established in 2002 that mandates best practices in financial record keeping and inventory reporting for corporations. Sarbanes-Oxley or (SOX) was introduced and passed by Senator Paul Sarbanes (D-MD) and Representative Michael Oxley (R-OH) after multiple corporate accounting scandals that occurred in the late 90s and early 2000s. Most notably, the Enron scandal brought to light the depth and seriousness of corporate malfeasance in what was largely an unregulated business environment. The impacts created by Enron’s corruption reverberated throughout the energy industry ultimately costing taxpayers hundreds of millions of dollars. What can inventory specialists, managers and warehouse staff do to protect themselves, their company and follow this law to the letter?

Carrier Pricing amid a Pandemic

In this era of increasing congestion, resource backlog and limited driver availability, carriers are adjusting their pricing models, and they are correct to do so. More importantly, carriers have an opportunity to develop their business model while simultaneously developing strong relationships during today’s unprecedented challenges in the industry.

Business Hours

- Monday – FridayOpen

- Saturday – SundayAppointments only